Types of Water Tank

Types of Water Tank

Introduction

Water tanks are used to store water for various purposes such as drinking, irrigation, firefighting, and industrial processes. They come in different shapes, sizes, and materials. In this article, we will discuss the different types of water tanks based on their location, materials, and shape.

Water Tank based on Location

Overhead Tank

Overhead tanks are placed above the head level. They are usually placed over the rooftop, terrace, and loft of the building. They are also built over the column or steel structures for the public water supply or for private use.

Ground-level Tank

Ground-level tanks are built or positioned over the ground level. They are used in residential buildings to store water, as curing tanks in industrial units, in the agricultural field for irrigation purposes, in aquaculture for fish breeding, and so on.

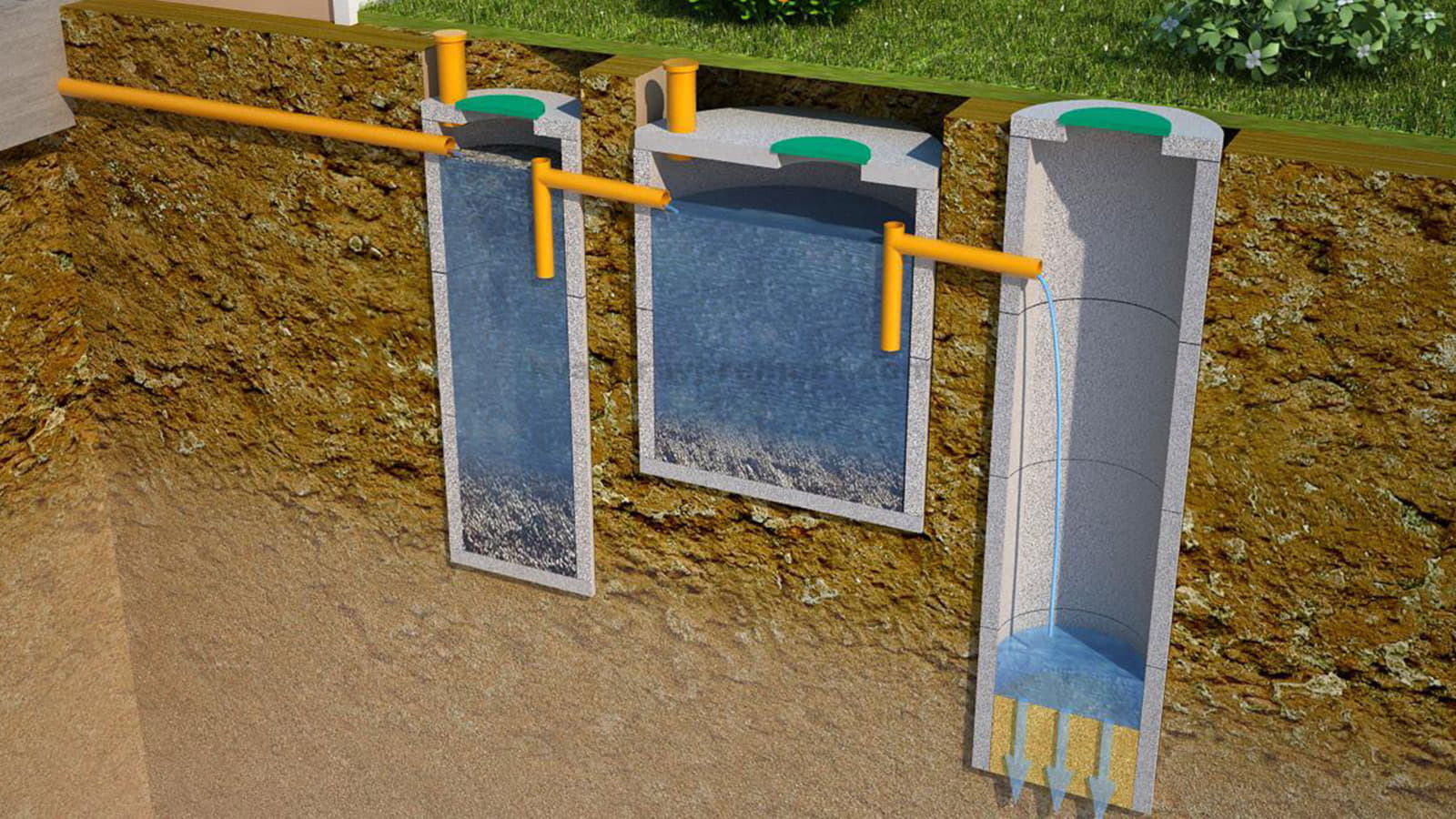

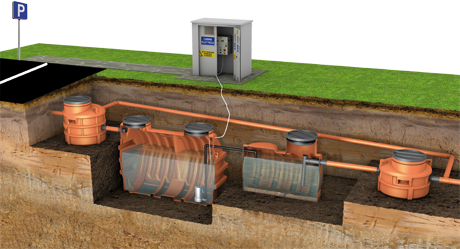

Underground Tank

Underground tanks are built or positioned beneath the ground level. They are used in residential buildings, commercial buildings, and industrial units.

Water Tank based on Materials

RCC Water Tank

RCC water tanks are made of reinforced cement concrete. They are further subdivided into:

Cast in situ RCC Tank

These are the water tanks that are built on the actual site using RCC materials.

Precast RCC Tank

These are the RCC water tanks that are produced in the manufacturing units and shifted to the site wherever necessary.

Masonry Water Tank

Masonry water tanks are constructed by using building bricks or blocks on the site locations. They are usually smaller in dimensions when compared to the RCC water tanks.

Steel Water Tank

Steel water tanks are mostly used for industrial purposes and in public water supply systems. They are further categorized as:

Stainless Steel Water Tank

They are used for specific purposes since the manufacturing cost is on the higher side. They are usually smaller in size when compared to the other types of water tanks due to their higher price range.

Mild Steel (MS) Water Tank

They are largely used for industrial purposes and in public water supply systems. The water tankers are fitted with MS material tanks for the supply of water. They are larger, and heavier, and can be fabricated into different shapes and sizes.

Plastic Water Tank

Plastic water tanks are the most commonly known water tank nowadays and they are replacing all other types of water tanks. They are made up of different types of plastic composites and polymers as per the required specification.

Water Tank based on Shape

Circular Water Tank

Circular water tanks have become indispensable in the world of water storage, offering a range of advantages that cater to diverse needs. From residential to industrial applications, their structural efficiency and space-saving design make them a popular choice. In this article, we'll delve into the intricacies of circular water tanks, exploring their types, design considerations, installation processes, and much more.

I. Introduction

A. Definition of Circular Water Tanks

Circular water tanks, as the name suggests, are cylindrical structures designed to store and distribute water. Their circular shape provides structural stability, making them an ideal choice for various settings.

B. Importance in Water Storage

With the increasing demand for efficient water storage solutions, circular water tanks have emerged as a reliable option. Their design ensures optimal use of space while maintaining stability and durability.

II. Advantages of Circular Water Tanks

A. Space Efficiency

Circular water tanks are space-efficient, maximizing storage capacity within a compact footprint. This makes them suitable for areas with limited space without compromising on water storage needs.

B. Structural Stability

The cylindrical shape of these tanks enhances their structural stability, providing resilience against external forces such as wind and seismic activities. This feature is crucial for ensuring the longevity of the tank.

C. Cost-Effectiveness

Circular water tanks often prove to be cost-effective in terms of construction and maintenance. The simplicity of their design and the use of durable materials contribute to their economic viability.

III. Types of Circular Water Tanks

A. Elevated Circular Water Tanks

Elevated circular water tanks are raised above the ground level, offering gravity-fed water distribution. This type is common in urban and hilly areas, ensuring efficient water supply to lower elevations.

B. Ground-Level Circular Water Tanks

Ground-level circular water tanks are installed directly on the ground. They are suitable for areas where elevation is not a concern and offer easy accessibility for maintenance and cleaning.

IV. Design Considerations

A. Material Selection

Choosing the right materials for circular water tank construction is crucial. Common materials include concrete, steel, and fiberglass. Each material has its own set of advantages, considering factors such as durability and cost.

B. Reinforcement Techniques

Reinforcement techniques are employed to enhance the structural integrity of circular water tanks. This includes the use of reinforcing bars and mesh, ensuring the tank can withstand external pressures.

C. Capacity Planning

Determining the required capacity of the tank is a critical aspect of the design process. Factors such as water demand, usage patterns, and future expansion plans need to be considered for effective capacity planning.

V. Installation Process

A. Site Preparation

Before installation, proper site preparation is essential. This involves clearing the area, leveling the ground, and ensuring a stable foundation for the tank.

B. Foundation Construction

The foundation is a key component in the stability of circular water tanks. Depending on the type of tank and soil conditions, the foundation may be a concrete slab or piers.

C. Tank Assembly

Once the site and foundation are ready, the tank assembly takes place. This involves erecting the circular structure, connecting components, and ensuring a watertight seal.

VI. Maintenance Tips

A. Regular Inspection

Routine inspections are crucial for identifying potential issues early on. Inspecting for leaks, corrosion, and structural integrity ensures the long-term functionality of the circular water tank.

B. Cleaning Procedures

Regular cleaning prevents the buildup of sediment and contaminants. Depending on the material, cleaning methods may vary, and adherence to recommended cleaning schedules is vital.

C. Repairs and Upkeep

Prompt repairs and upkeep contribute to the longevity of circular water tanks. Addressing issues such as leaks or damaged components immediately prevents further deterioration.

VII. Circular Water Tanks in Different Industries

A. Agriculture

Circular water tanks play a vital role in agricultural settings, providing a reliable water source for irrigation and livestock. Their efficiency in space utilization aligns well with the often-limited space on farms.

B. Residential

In residential areas, circular water tanks offer a sustainable solution for water storage. They can be seamlessly integrated into the landscape, providing an efficient and aesthetically pleasing option.

C. Industrial Applications

Industries rely on circular water tanks for various processes, including manufacturing and cooling systems. Their structural stability and capacity make them suitable for diverse industrial needs.

VIII. Environmental Impact

A. Sustainability Features

Circular water tanks can be designed with sustainability in mind. Implementing features such as rainwater harvesting systems enhances their eco-friendly profile, contributing to water conservation.

B. Water Conservation Benefits

Efficient water storage and distribution contribute to water conservation efforts. Circular water tanks, by virtue of their design and functionality, support sustainable water usage practices.

IX. Case Studies

A. Successful Circular Water Tank Projects

Exploring successful circular water tank projects provides insights into real-world applications. Case studies highlight challenges faced, innovative solutions, and the positive impact these tanks have had.

B. Real-world Applications

Examining the diverse real-world applications of circular water tanks showcases their adaptability and effectiveness in addressing unique challenges in different settings.

X. Future Trends

A. Technological Innovations

Advancements in technology continue to influence the design and functionality of circular water tanks. Smart monitoring systems and innovative materials are shaping the future of water storage.

B. Sustainable Practices

The future of circular water tanks aligns with sustainable practices. Incorporating eco-friendly materials, energy-efficient processes, and holistic water management approaches will define the next generation of these tanks.

Square Water Tank

Water, a precious resource, is essential for daily life. As the demand for water continues to rise, so does the need for efficient storage solutions. One such innovation making waves in the industry is the square water tank. In this article, we'll explore the advantages, considerations, and the future of square water tanks, providing a comprehensive guide for anyone considering this modern water storage solution.

A. Definition of Square Water Tank

A square water tank is a container designed for the purpose of storing water in a square or rectangular shape. Unlike traditional round tanks, square tanks offer unique advantages in terms of space efficiency and stability.

B. Importance of Water Storage

Water storage is crucial for both residential and commercial purposes. Whether for household use, agricultural needs, or industrial applications, having an efficient and reliable water storage system is essential to ensure a stable water supply.

II. Advantages of Square Water Tanks

A. Space Efficiency

One of the primary advantages of square water tanks is their space efficiency. Unlike round tanks, square tanks can be easily placed against walls or in corners, making them ideal for properties with limited space.

B. Stability and Durability

The square shape of these tanks provides inherent stability. This design minimizes the risk of tipping or rolling, ensuring the durability and longevity of the tank.

C. Easy Installation

Square water tanks are known for their straightforward installation process. The design allows for easy fitting into various spaces, and the installation can often be done without the need for extensive professional assistance.

III. Choosing the Right Size

A. Household Needs

Selecting the right size of a square water tank depends on the specific needs of the household. Consider factors such as daily water consumption, the number of residents, and the availability of space.

B. Commercial Applications

For commercial purposes, a thorough assessment of water requirements is essential. Square tanks offer scalability, making them suitable for businesses with fluctuating water needs.

IV. Material Matters

A. Types of Materials

Square water tanks are available in various materials, including plastic, fiberglass, and concrete. Each material has its own set of pros and cons, influencing factors such as cost, weight, and durability.

B. Pros and Cons

Understanding the advantages and disadvantages of each material helps in making an informed decision based on specific requirements and budget constraints.

V. Maintenance Tips

A. Cleaning and Disinfection

Regular cleaning and disinfection are critical to maintaining water quality. Square tanks, with their accessible corners, facilitate thorough cleaning to ensure the purity of stored water.

B. Inspections and Repairs

Routine inspections help identify potential issues early on. Prompt repairs can prevent leaks and extend the lifespan of the tank.

VI. Square Water Tanks vs. Traditional Round Tanks

A. Cost Comparison

While square water tanks may have a slightly higher initial cost, their long-term benefits often outweigh the investment. A cost comparison analysis helps in understanding the overall value.

B. Aesthetics and Design

The square shape of these tanks adds a modern and sleek aesthetic to properties, offering a visually pleasing alternative to traditional round tanks.

VII. Environmental Impact

A. Rainwater Harvesting

Square water tanks play a vital role in rainwater harvesting. The efficient design allows for easy collection and storage of rainwater, promoting sustainable water usage.

B. Sustainable Practices

Embracing square water tanks aligns with sustainable water management practices, contributing to environmental conservation efforts.

VIII. Installation Process

A. Professional Installation

For those not confident in DIY installation, seeking professional assistance ensures a seamless and secure setup of the square water tank.

B. DIY Installation Tips

For the DIY enthusiasts, following proper guidelines and safety measures is crucial for a successful installation process.

IX. Common Issues and Solutions

A. Leakage Problems

Addressing leakage issues promptly is essential to prevent water wastage and potential damage to surrounding areas.

B. Water Quality Concerns

Implementing water filtration systems and adhering to maintenance schedules helps in ensuring consistently high water quality.

X. Regulatory Compliance

A. Local Regulations

Before installing a square water tank, it's crucial to be aware of and comply with local regulations regarding water storage.

B. Safety Standards

Adhering to safety standards ensures the secure installation and operation of square water tanks.

XI. Square Water Tanks in Urban Planning

A. Integration in Urban Spaces

The space-efficient design of square water tanks makes them suitable for integration into urban planning, addressing the challenge of limited space.

B. Smart Water Management

Incorporating technology for smart water monitoring enhances efficiency and aids in sustainable water management in urban areas.

XII. Case Studies

A. Successful Implementations

Exploring real-life case studies highlights the successful integration of square water tanks in various settings.

B. User Experiences

Understanding the experiences of individuals or businesses using square water tanks provides valuable insights into their practicality and effectiveness.

XIII. Future Trends

A. Technological Advancements

Ongoing advancements in technology may bring innovations such as smart sensors and automated monitoring to enhance the functionality of square water tanks.

B. Innovations in Design

Continual improvements in design may lead to even more efficient and aesthetically pleasing square water tank options in the future.

XIV. Cost Considerations

A. Initial Investment

While the initial cost of square water tanks may vary, the long-term benefits, including reduced water bills and maintenance costs, contribute to overall savings.

B. Long-Term Savings

Calculating the long-term savings associated with square water tanks provides a holistic understanding of their financial benefits.

Rectangular Water Tank

Water storage is a critical aspect of our daily lives, whether for residential, commercial, or agricultural purposes. In this article, we'll delve into the world of rectangular water tanks, exploring their advantages, how to choose the right size, materials used, installation process, maintenance tips, and much more.

Advantages of Rectangular Water Tanks

Space Utilization

Rectangular water tanks stand out for their efficient use of space. Unlike cylindrical tanks, they can be easily fitted into corners or against walls, optimizing the available area.

Ease of Installation

Installing a rectangular water tank is a hassle-free process. Their design allows for straightforward placement and connection, reducing installation time and costs.

Cost-Effectiveness

Cost is a crucial factor in any purchase decision. Rectangular water tanks often prove to be more budget-friendly than their counterparts, making them a practical choice without compromising quality.

Choosing the Right Size

When selecting a rectangular water tank, various factors come into play. Considerations such as water usage, available space, and future needs must be factored in. We'll guide you through the calculations to determine the optimal capacity for your requirements.

Materials Used in Rectangular Water Tanks

The choice of materials significantly influences the durability and lifespan of a water tank. From traditional options like concrete to modern alternatives like polyethylene, we'll explore the pros and cons of each, helping you make an informed decision.

Installation Process

Our step-by-step guide simplifies the installation process, providing valuable insights into positioning, connecting plumbing, and addressing potential challenges. Don't let installation intimidate you; we've got you covered.

Maintenance Tips

Ensuring the longevity of your rectangular water tank requires regular maintenance. Learn how to conduct inspections, address common issues, and implement best practices to keep your tank in top condition.

Applications of Rectangular Water Tanks

From residential water storage to industrial and agricultural applications, rectangular water tanks find diverse uses. Discover the versatility of these tanks and how they cater to different needs.

Comparison with Other Tank Shapes

How do rectangular water tanks stack up against circular and cylindrical counterparts? We'll break down the advantages and disadvantages, helping you make an informed decision based on your specific requirements.

Environmental Impact

Sustainability is a growing concern. Explore the environmental features of rectangular water tanks and discover recycling options for the materials used in their construction.

Innovations in Rectangular Water Tank Design

Stay updated on the latest technologies and design improvements in rectangular water tanks. From smart monitoring systems to advanced materials, innovation is shaping the future of water storage.

Cost Considerations

While the initial cost is a crucial factor, we'll delve into the long-term savings associated with rectangular water tanks. Understand the various elements that contribute to the overall cost and make a decision that aligns with your budget.

Regulatory Compliance

Adhering to guidelines and regulations is paramount when installing a water tank. Gain insights into the regulatory landscape, ensuring your rectangular water tank meets all necessary standards.

Customer Testimonials

Real-world experiences speak volumes. Read testimonials from satisfied customers who have benefited from the efficiency and reliability of rectangular water tanks.

Common Misconceptions

Dispelling myths is essential for making informed decisions. We address common misconceptions about rectangular water tanks, providing clarity on their functionality and advantages.

Future Trends

What does the future hold for rectangular water tanks? Explore anticipated developments in technology and design that will shape the landscape of water storage in the years to come.

Intez Water Tank

Key Features of Intez Water Tanks

Intez Water Tanks are renowned for their superior quality and innovative design. The tanks are crafted from high-quality materials, ensuring durability and longevity. With various size options available, Intez caters to a wide range of water storage needs, from residential to commercial and agricultural.

Advantages of Choosing Intez Water Tanks

Reliability and Longevity

Intez Water Tanks are built to last. The use of advanced materials and innovative manufacturing processes ensures the tanks can withstand the test of time, providing a reliable and long-lasting solution for water storage.

Cost-Effectiveness

Investing in an Intez Water Tank proves to be cost-effective in the long run. The durability of the materials and the low maintenance requirements contribute to significant savings over the tank's lifespan.

Ease of Installation and Maintenance

Intez Water Tanks come with a user-friendly installation process. The tanks are designed for easy setup, and maintenance is simplified with guidelines for regular cleaning, inspections, and troubleshooting common issues.

Material Technology

Intez Water Tanks incorporate cutting-edge material technology. The tanks utilize advanced materials that not only enhance durability but also contribute to the overall performance of the tank. The technology ensures that the tank remains robust and efficient under various conditions.

Intez Water Tank Installation Process

Installing an Intez Water Tank is a straightforward process. Our step-by-step guide provides clear instructions for positioning the tank and connecting plumbing. Whether you're a DIY enthusiast or prefer professional installation, Intez makes the process hassle-free.

Maintenance and Care Tips

To ensure the longevity of your Intez Water Tank, follow our maintenance and care tips. Regular cleaning and inspections are key to preventing issues, and our troubleshooting guide helps address common issues promptly.

Applications of Intez Water Tanks

Intez Water Tanks cater to diverse applications. From meeting residential water storage needs to serving commercial, industrial, and agricultural purposes, Intez offers a versatile solution for various consumers.

Customer Satisfaction Stories

Discover the experiences of satisfied customers who have chosen Intez Water Tanks. Real-world testimonials highlight the performance, reliability, and overall satisfaction with Intez products.

Comparison with Other Brands

Compare Intez Water Tanks with other brands in the market. Explore the advantages and unique features that set Intez apart, helping you make an informed decision.

Environmental Sustainability

Intez is committed to environmental sustainability. Learn about the eco-friendly aspects of Intez Water Tanks and explore recycling options for the materials used in their construction.

Innovations and Future Developments

Stay ahead with Intez's innovations. Explore the latest technological advancements in water tank design and get a glimpse of what the future holds for Intez Water Tanks.

Cost-Effective Solutions

Analyze the cost-effectiveness of choosing Intez Water Tanks. Consider the initial investment versus long-term savings to make a decision that aligns with your budget and needs.

Warranty and Customer Support

Intez stands by its products with comprehensive warranties. Learn about the details of warranties offered and the quality of customer support available to assist you.

Common Misconceptions about Intez Water Tanks

Dispelling myths is essential for clarity. Addressing common misconceptions about Intez Water Tanks ensures that consumers have accurate information when making their purchase decisions.

Spherical Tank

Spherical tanks, often referred to as round tanks or globular tanks, boast a design that deviates from the conventional cylindrical or rectangular tanks. The curvature of these tanks, resembling a perfect sphere, holds more than aesthetic appeal; it serves a multitude of functional purposes. In the next sections, we will explore the intricacies of these remarkable structures, their applications, and the impact they've made on diverse industries.

Design and Structure

The spherical shape of these tanks isn't merely a stylistic choice. It has inherent advantages that contribute to the tank's structural integrity and overall efficiency. The materials used in constructing spherical tanks are carefully selected to ensure durability and longevity. The seamless design reduces stress points, making them more resistant to pressure and external forces.

Applications

Oil and Gas Storage

One of the primary applications of spherical tanks lies in the oil and gas industry. Their efficient use of space allows for substantial storage capacity without occupying vast areas. This not only reduces the environmental footprint but also enhances cost-effectiveness.

Industrial Processing

Beyond oil and gas, spherical tanks find applications in various industrial processes. Chemical storage, liquid containment, and gas processing benefit from the space efficiency and structural stability offered by these tanks.

Aerospace Applications

The aerospace industry has also embraced the spherical tank concept. From spacecraft design to microgravity experiments, the unique shape of these tanks proves advantageous in a realm where every inch and ounce matter.

Advantages Over Traditional Tanks

Space Efficiency

Spherical tanks occupy less ground space compared to their traditional counterparts, making them ideal for locations where space is a premium. This efficiency in footprint allows for more versatile placement and increased storage capacity.

Reduced Stress Points

The absence of corners in spherical tanks significantly reduces stress points, enhancing their structural strength. This feature not only contributes to the tank's durability but also makes them more resistant to environmental pressures.

Enhanced Safety Features

The shape of spherical tanks, combined with advanced safety measures, makes them inherently safer than traditional tanks. The reduced risk of leaks and structural failures ensures a secure storage and processing environment.

Challenges and Solutions

While spherical tanks offer numerous advantages, they aren't without challenges. Transporting these tanks, especially in large sizes, presents logistical difficulties. Specialized installation requirements add to the complexity. However, the industry has responded with innovative solutions, including modular designs and advanced transportation methods.

Spherical Tank in Oil and Gas Industry

Storage Capacity

Spherical tanks excel in providing substantial storage capacity for oil and gas. The rounded shape maximizes volume while minimizing surface area, reducing heat exchange and maintaining product quality.

Cost-Effectiveness

Despite initial installation costs, spherical tanks prove cost-effective over time due to their efficient use of space and lower maintenance requirements.

Environmental Considerations

The environmental impact of spherical tanks is a crucial consideration. As industries strive for sustainability, these tanks offer a greener alternative with reduced land usage and optimized resource management.

Industrial Processing Applications

Chemical Storage

Chemical industries benefit from spherical tanks' ability to store a variety of substances safely. The shape is particularly advantageous for corrosive or volatile materials.

Liquid and Gas Containment

The seamless design of spherical tanks makes them suitable for storing liquids and gases without the risk of leaks or contamination. This is essential in industries where purity and consistency are paramount.

Temperature Regulation

Spherical tanks can be designed to accommodate temperature-regulated substances, further expanding their applications in industries where precise control over storage conditions is essential.

Spherical Tanks in Aerospace

Use in Spacecraft Design

The aerospace industry leverages the benefits of spherical tanks in spacecraft design. The rounded shape optimizes storage in confined spaces and enhances the overall efficiency of the spacecraft.

Microgravity Applications

In microgravity environments, such as space stations or research laboratories, spherical tanks provide stability and reliability in storing essential supplies and conducting experiments.

Future Possibilities

The use of spherical tanks in aerospace is likely to expand, with ongoing research exploring innovative applications and improved technologies.

Maintenance and Inspection

Regular maintenance and inspection are crucial for ensuring the longevity of spherical tanks. Protocols for inspections, repairs, and preventive measures are in place to address any wear and tear promptly.

Future Trends in Spherical Tank Technology

As technology evolves, so do spherical tanks. Advancements in materials, construction techniques, and integration with smart systems are shaping the future of these storage and processing solutions. Sustainability is a key focus, with efforts to make spherical tanks even more eco-friendly.

Case Studies

Examining successful implementations of spherical tanks provides valuable insights into their practical advantages. Notable projects in various industries offer lessons learned and best practices for future applications.

Spherical Tank Regulations

Safety Standards

Strict safety standards govern the design, construction, and operation of spherical tanks. Compliance with these standards is essential to ensure the safety of personnel and the surrounding environment.

Environmental Regulations

In addition to safety standards, spherical tanks must adhere to environmental regulations. These regulations address issues such as emissions, waste disposal, and land use, aligning with global efforts toward sustainability.

Compliance Requirements

Industries utilizing spherical tanks must meet specific compliance requirements set by regulatory bodies. This ensures a standardized approach to safety and environmental responsibility.

The Environmental Impact

Considering the environmental impact of spherical tanks is vital in today's eco-conscious world. The carbon footprint of these tanks, along with considerations for recycling and reuse, contributes to their overall sustainability.

Carbon Footprint

Compared to traditional tanks, spherical tanks often have a lower carbon footprint due to their space efficiency and optimized resource use.

Recycling Considerations

The materials used in spherical tanks can be recycled, further reducing their environmental impact. The recycling process aligns with the circular economy concept, promoting sustainability.

Eco-Friendly Innovations

Ongoing research focuses on developing eco-friendly innovations in spherical tank technology, aiming to minimize environmental impact and promote responsible resource management.

Conical Bottom Type Tank

Conical bottom type tanks, a versatile and efficient storage solution, have gained prominence across various industries. These tanks, characterized by their cone-shaped bottom, offer unique advantages that cater to specific needs. Let's dive into the design features, applications, and benefits of conical bottom tanks.

Design Features

Conical bottom tanks are meticulously designed with a distinctive cone-shaped base. This design facilitates efficient drainage, making these tanks ideal for processes that require complete liquid evacuation. The choice of materials for these tanks varies, including stainless steel, polyethylene, and fiberglass, providing options that suit different industry requirements. Additionally, conical bottom tanks come in a range of capacities and sizes, offering flexibility in storage options.

Advantages of Conical Bottom Tanks

Efficient Drainage

The conical shape of the tank bottom ensures gravity-driven drainage, leaving minimal residue. This feature is particularly beneficial in processes where thorough cleaning is essential.

Mixing Capabilities

Conical bottom tanks promote effective mixing of liquids, a crucial aspect in industries such as pharmaceuticals and chemicals. The shape encourages natural convection currents, enhancing the homogeneity of the stored substances.

Space-Saving Design

The space-saving design of conical bottom tanks is advantageous in facilities where floor space is a premium. These tanks can be strategically placed without compromising efficiency.

Applications in Various Industries

Conical bottom tanks find applications across diverse industries, each leveraging the unique benefits offered by this design.

Chemical Industry

In the chemical industry, conical bottom tanks are preferred for storing and processing chemicals. The efficient drainage and mixing capabilities ensure optimal performance in various chemical processes.

Food and Beverage Industry

The food and beverage industry benefits from conical bottom tanks, especially in the production of beverages and liquid food items. The design supports easy cleaning and prevents residue buildup.

Pharmaceutical Industry

Pharmaceutical companies utilize conical bottom tanks for the production of medicines and other liquid pharmaceutical products. The hygienic design is crucial in maintaining product integrity.

Installation and Maintenance

Proper installation is key to maximizing the performance of conical bottom tanks. Following industry-standard procedures ensures stability and longevity. Regular maintenance, including inspections and cleaning, further contributes to the durability of these tanks.

Choosing the Right Conical Bottom Tank

Several factors should be considered when selecting a conical bottom tank, including the type of liquid to be stored, the required capacity, and specific customization options. Consulting with experts in tank design can assist in making informed decisions.

Case Studies

Real-world examples demonstrate the success of conical bottom tanks in various industries. Case studies highlight specific challenges faced by businesses and the positive outcomes achieved through the implementation of these tanks.

Comparison with Other Tank Types

To provide a comprehensive view, it's essential to compare conical bottom tanks with other tank designs, such as flat-bottom tanks. Understanding the pros and cons aids in making informed choices based on specific industry needs.

Future Trends and Innovations

The industry is witnessing ongoing innovations in tank design, including conical bottom tanks. Sustainability and eco-friendly options are becoming increasingly important, with new technologies focusing on reducing environmental impact.

Common Misconceptions

Addressing misconceptions is crucial in promoting the widespread adoption of conical bottom tanks. Debunking myths and clarifying misunderstandings ensures that industries make decisions based on accurate information.

Safety Considerations

Safety is paramount in any industrial setting. Ensuring that conical bottom tanks are handled and used according to safety standards is essential. Compliance with regulations guarantees a secure working environment.

Customer Testimonials

Feedback from industries already using conical bottom tanks provides valuable insights. Customer testimonials share real-world experiences, detailing the advantages and satisfaction levels achieved with these tanks.

Expert Opinions

Industry experts contribute their insights on the benefits of conical bottom tanks. Their recommendations guide businesses in optimizing the use of these tanks for enhanced efficiency and productivity.

Cost-Benefit Analysis

Evaluating the economic aspects of choosing conical bottom tanks involves considering initial costs, maintenance expenses, and the long-term return on investment. A thorough analysis assists businesses in making financially sound decisions.

Polygon Water Tank

Water is an invaluable resource, and efficient storage solutions are crucial to ensure a reliable supply for households, industries, and agriculture. One innovative solution gaining popularity is the polygon water tank. In this comprehensive guide, we'll explore the benefits, materials, installation process, and much more.

Benefits of Polygon Water Tanks

Space Optimization

Polygon water tanks, with their unique shapes, are designed to maximize space utilization. Unlike traditional round or rectangular tanks, polygon tanks can fit into corners or irregular spaces, making them ideal for urban areas with limited space.

Structural Integrity

The polygon design isn't just about aesthetics; it enhances the tank's structural integrity. The multiple angles and reinforced edges provide added strength, ensuring the tank can withstand various environmental conditions.

Aesthetics

Beyond functionality, polygon tanks offer aesthetic appeal. Their modern design seamlessly blends with contemporary architecture, making them a visually pleasing addition to any property.

Material Matters: What Are Polygon Water Tanks Made Of?

Choosing the right material is crucial for the longevity and efficiency of a water tank. Polygon water tanks are commonly made of high-density polyethylene (HDPE), fiberglass, or steel.

High-Density Polyethylene (HDPE)

Known for its durability and resistance to corrosion, HDPE is a popular choice. It's lightweight, making installation easier, and its non-toxic nature ensures the stored water remains safe for consumption.

Fiberglass

Fiberglass tanks are known for their strength and resistance to rust. They are relatively low-maintenance and can withstand harsh weather conditions, making them suitable for outdoor use.

Steel

Steel tanks are sturdy and have a long lifespan. They are often chosen for large-scale industrial applications. However, they may require additional coatings to prevent corrosion.

Choosing the Right Size and Shape

Selecting the appropriate size and shape of a polygon water tank involves considering the water needs and the available space for installation. Assessing the required water capacity and ensuring the tank fits seamlessly into the designated space are critical steps in the decision-making process.

Installation Process Demystified

The installation of a polygon water tank involves several key steps to ensure proper functionality and longevity.

Foundation Preparation

A stable foundation is essential. Depending on the tank material, this may involve a concrete pad or a leveled surface. Proper preparation ensures the tank remains secure and prevents uneven settling.

Assembly Steps

Following the manufacturer's guidelines, the tank is assembled piece by piece. This process may vary based on the material, but it typically involves securing the panels together and adding any necessary reinforcements.

Safety Precautions

During installation, safety should be a top priority. Proper equipment and adherence to safety protocols are essential to prevent accidents and ensure a successful installation.

Maintenance Tips for Longevity

Regular maintenance is crucial for the longevity and efficiency of polygon water tanks.

Cleaning Procedures

Cleaning the tank at regular intervals prevents the buildup of sediment and contaminants. Depending on the material, specific cleaning agents may be recommended.

Inspection Checklist

Regular inspections help identify potential issues early. Check for signs of wear, corrosion, or leaks. Addressing problems promptly can prevent costly repairs or replacements.

Repair Guidelines

In the event of damage, follow the manufacturer's repair guidelines. Most issues can be addressed with timely and appropriate repairs, extending the tank's lifespan.

Comparing Polygon Tanks with Traditional Options

Round Tanks

Traditional round tanks are common, but their design may not be the most efficient for all spaces. They lack the space optimization and modern aesthetic appeal of polygon tanks.

Rectangular Tanks

While rectangular tanks offer some space efficiency, they may not match the structural integrity and visual appeal of polygon tanks.

Advantages and Disadvantages

Explore the pros and cons of each type to make an informed decision based on individual needs and preferences.

Eco-Friendly Aspects of Polygon Water Tanks

Sustainability Features

Many polygon tanks are designed with sustainability in mind. Look for features such as rainwater harvesting systems and eco-friendly materials.

Recycling Options

When the time comes to replace a tank, consider recycling options. Many tank materials are recyclable, contributing to environmental sustainability.

Cost Considerations

Initial Investment

While polygon water tanks may have a higher initial cost, their long-term benefits, including durability and space optimization, often outweigh the upfront expense.

Long-Term Savings

Factor in the potential savings over time. Efficient water storage can lead to reduced water bills and lower maintenance costs, making polygon tanks a cost-effective choice in the long run.

Real-life Case Studies

Successful Implementations

Explore real-life examples where polygon water tanks have been successfully implemented. Learn from the experiences of others to make informed decisions.

User Testimonials

Hear from individuals and businesses that have chosen polygon water tanks. Their firsthand experiences can provide valuable insights into the performance and benefits of these innovative storage solutions.

Addressing Common Concerns

Durability Questions

Address common concerns about the durability of polygon water tanks. Highlight the reinforced design and durable materials that contribute to their long lifespan.

Potential Leaks

Assure readers about the tight seals and quality construction that minimize the risk of leaks in polygon water tanks.

Weather Resistance

Discuss the weather-resistant features of polygon tanks, emphasizing their ability to withstand diverse environmental conditions.

Innovations in Polygon Water Tank Technology

Smart Tank Features

Explore the latest technological advancements in polygon water tanks, including smart features that provide real-time monitoring and control.

IoT Integration

Some polygon tanks can be integrated into IoT systems, offering advanced connectivity and control options for users.

Regulatory Compliance and Safety Standards

Industry Norms

Highlight the importance of choosing tanks that meet industry standards and regulations to ensure safety and compliance.

Legal Requirements

Provide information on any legal requirements related to the installation and use of polygon water tanks in different regions.

Future Trends in Water Storage

Technological Advancements

Discuss upcoming technologies that may impact the design and functionality of water storage solutions.

Sustainability Initiatives

Explore how the industry is moving towards more sustainable practices and how this may influence the future of water storage.

Conclusion

Water tanks are an essential part of our daily lives. They are used to store water for various purposes such as drinking, irrigation, firefighting, and industrial processes. They come in different shapes, sizes, and materials. The choice of water tank depends on the purpose, location, and budget. By understanding the different types of water tanks, we can make an informed decision while choosing the right water tank for our needs.

FAQs

- What are water tanks? Water tanks are used to store water for various purposes such as drinking, irrigation, firefighting, and industrial processes.

- What are the different types of water tanks based on location? The different types of water tanks based on location are overhead tank, ground-level tank, and underground tank.

- What are the different types of water tanks based on materials? The different types of water tanks based on materials are RCC water tank, masonry water tank, steel water tank, and plastic water tank.

- What are the different types of water tanks based on shape? The different types of water tanks based on shape are circular water tank, square water tank, rectangular water tank, intez water tank, spherical tank, conical bottom type tank, and polygon water tank.

- What are the factors to consider while choosing a water tank? The factors to consider while choosing a water tank are purpose, location, and budget.

- Q: What is the lifespan of a typical water tank?

- A: The lifespan varies based on the material and maintenance, but many tanks can last 20 years or more.

- Q: Are there any government regulations for water tank installations?

- A: Regulations vary by location, so it's crucial to check with local authorities to ensure compliance.

- Q: Can I use rainwater collected in my tank for drinking purposes?

- A: With proper filtration systems, rainwater can be made potable, but it's essential to follow health guidelines.

- Q: How often should I clean my water tank?

- A: Regular inspections and cleanings are recommended at least once a year to maintain water quality.

- Q: Are there tax incentives for installing eco-friendly water storage solutions?

- A: In some regions, there are tax incentives or rebates for implementing sustainable water practices.

In conclusion, choosing the right water tank involves careful consideration of various factors. Whether for residential, commercial, or industrial use, understanding the types, materials, and maintenance requirements ensures a reliable and sustainable water storage solution. As technology advances, the future promises even more innovative and eco-friendly options for meeting our water storage needs.

Comments

Post a Comment