UNDERSTANDING INDUSTRIAL OILS

Industrial oils play a crucial role in various manufacturing processes, providing lubrication and ensuring the smooth operation of machinery. From hydraulic systems to gear assemblies, these oils are the lifeblood of many industries. In this article, we will delve into the intricacies of industrial oils, exploring their types, properties, applications, and the critical factors to consider when selecting and using them.

Introduction

Industrial oils, often referred to as lubricants, are specialized liquids designed to reduce friction, wear, and heat in mechanical systems. They are a vital component in ensuring the longevity and efficiency of industrial machinery. Understanding the nuances of these oils is essential for businesses seeking to optimize their manufacturing processes.

Types of Industrial Oils

Hydraulic Oils

Hydraulic oils are formulated to transmit power within hydraulic machinery. They possess excellent viscosity characteristics and thermal stability, making them ideal for applications where varying temperatures and pressures are commonplace.

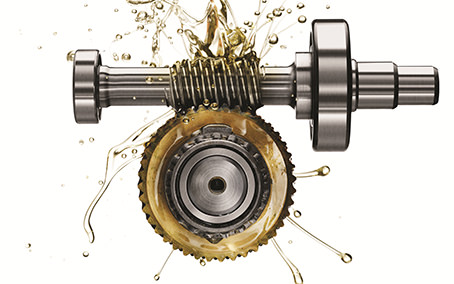

Gear Oils

Gear oils are tailored to lubricate gears and bearings, preventing wear and ensuring smooth operation. Their composition is such that they adhere well to gear surfaces, providing a protective barrier against friction and heat.

Compressor Oils

Compressor oils are designed for use in air compressors, where they assist in heat dissipation and reduce wear on moving parts. Their anti-foaming properties make them suitable for high-pressure environments.

Turbine Oils

Turbine oils are formulated to lubricate the intricate components of turbines, ensuring optimal performance. They are resistant to oxidation, maintaining their efficacy in demanding conditions.

Properties and Characteristics

Understanding the properties of industrial oils is crucial for selecting the right type for specific applications.

Viscosity

Viscosity, a measure of a fluid's resistance to flow, is a key property of industrial oils. It determines how well the oil can lubricate and flow through a system.

Thermal Stability

In high-temperature environments, thermal stability is paramount. Industrial oils with excellent thermal stability can withstand elevated temperatures without breaking down or losing their lubricating properties.

Oxidation Resistance

Oxidation can degrade the performance of industrial oils over time. Oils with high oxidation resistance maintain their quality, ensuring a longer service life.

Applications in Manufacturing

The applications of industrial oils in manufacturing are diverse and critical to the functioning of various machinery.

Machinery Lubrication

In manufacturing plants, machinery lubrication is essential to reduce friction, minimize wear, and prevent breakdowns. Industrial oils are tailored to specific equipment needs.

Heat Transfer Systems

Industrial oils are used in heat transfer systems to efficiently transfer and dissipate heat, maintaining optimal operating temperatures in industrial processes.

Metal Cutting and Forming

In metalworking, industrial oils aid in metal cutting and forming processes, reducing friction and heat generated during these operations.

Benefits of Using Industrial Oils

The utilization of industrial oils brings forth a range of benefits for businesses.

Extended Equipment Life

Proper lubrication with industrial oils can significantly extend the life of industrial equipment, reducing the need for frequent replacements.

Improved Efficiency

Efficient machinery operation is directly linked to proper lubrication. Industrial oils ensure smooth functioning, leading to increased overall efficiency.

Cost Savings

While the upfront cost of industrial oils may seem an investment, the long-term savings through reduced maintenance and increased equipment lifespan outweigh the initial expense.

Selecting the Right Industrial Oil

Choosing the appropriate industrial oil involves careful consideration of various factors.

Compatibility with Equipment

Different machinery requires different types of industrial oils. Compatibility with the equipment is paramount to ensure optimal performance.

Environmental Considerations

Businesses are increasingly mindful of environmental impact. Selecting industrial oils with eco-friendly formulations aligns with sustainable practices.

Industry Standards

Adhering to industry standards in oil selection ensures that the chosen lubricant meets specific quality and performance criteria.

Storage and Handling Best Practices

Even the best industrial oils require proper storage and handling to maintain their efficacy.

Temperature Control

Storing oils in controlled temperatures prevents degradation and ensures consistent viscosity.

Contamination Prevention

Contamination can compromise the quality of industrial oils. Implementing stringent contamination prevention measures is essential.

Regular Testing

Regular testing of industrial oils helps identify any deviations from the expected performance, allowing for timely corrective measures.

Common Challenges and Solutions

Despite the benefits, industrial oils may face challenges in their application.

Oil Contamination

Contamination from external sources can compromise the purity of industrial oils. Implementing effective filtration systems is crucial.

Lubrication Failure

Inadequate lubrication can lead to machinery failure. Regular inspections and adherence to lubrication schedules are vital to prevent such failures.

Monitoring and Maintenance

Regular monitoring and proactive maintenance practices are necessary to address potential issues before they escalate.

Recent Innovations in Industrial Oils

The field of industrial oils continues to evolve with technological advancements.

Bio-based Oils

Bio-based industrial oils, derived from renewable sources, offer an eco-friendly alternative with comparable performance.

Nanotechnology in Lubrication

Nanotechnology is being harnessed to enhance the lubricating properties of industrial oils, leading to improved efficiency and durability.

Environmental Impact

As businesses strive for sustainability, the environmental impact of industrial oils is a critical consideration.

Recycling and Disposal

Efforts towards recycling and proper disposal of used industrial oils contribute to environmental conservation.

Sustainable Practices

Adopting sustainable practices, such as using bio-based oils and minimizing waste, aligns with broader environmental goals.

Case Studies

Real-world examples highlight the successful implementation of industrial oils.

Successful Implementation Stories

Case studies showcase how businesses have benefited from the strategic use of industrial oils in their operations.

Lessons Learned

Examining lessons learned from past experiences provides valuable insights for businesses considering the implementation of industrial oils.

Future Trends in Industrial Oils

The future of industrial oils holds exciting possibilities.

Technological Advancements

Continued technological advancements are expected to bring forth even more efficient and specialized industrial oils.

Market Projections

The market for industrial oils is projected to grow, driven by increased industrialization and the demand for high-performance lubricants.

Expert Recommendations

Industry experts offer valuable recommendations for businesses navigating the world of industrial oils.

Industry Experts' Insights

Insights from experts provide practical guidance on selecting, using, and maintaining industrial oils.

Best Practices

Adopting best practices, as recommended by industry experts, ensures optimal outcomes in industrial oil applications.

Conclusion

Understanding industrial oils is paramount for businesses seeking to optimize their manufacturing processes. From selecting the right type for specific applications to implementing best practices in storage and handling, every aspect contributes to the overall efficiency and longevity of industrial machinery. As technology advances, so do the possibilities for even more sustainable and high-performance industrial oils.

FAQs

Q: How often should industrial oils be tested for quality?

- A: Regular testing is recommended, with intervals depending on the specific application and environmental conditions.

Q: Are bio-based industrial oils as effective as traditional ones?

- A: Yes, bio-based oils can offer comparable performance while being more environmentally friendly.

Q: What steps can businesses take to minimize the environmental impact of industrial oils?

- A: Implementing recycling programs and choosing eco-friendly formulations are effective measures.

Q: Can industrial oils be used interchangeably between different types of machinery?

- A: No, it's crucial to select oils compatible with the specific requirements of each type of machinery.

Q: How do technological advancements impact the formulation of industrial oils?

- A: Advancements lead to more efficient and specialized formulations, enhancing the overall performance of industrial oils.

Comments

Post a Comment