How Float Valves Work

Float valves, a fundamental component in fluid control systems, play a crucial role in maintaining water levels in various settings. Whether in industrial processes, agricultural irrigation, or household water tanks, float valves ensure a controlled and consistent flow of water. In this article, we'll delve into the intricacies of how float valves work, their types, applications, advantages, challenges, and future trends.

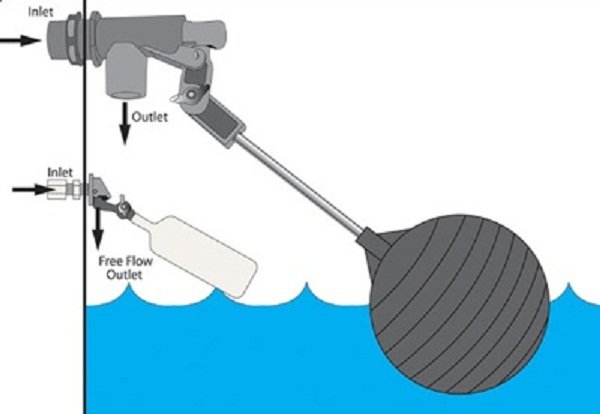

The Basics of Float Valves

Float valves, also known as ball cocks, operate on a simple yet effective principle. They consist of a valve connected to a float. As water levels rise, the float also rises, causing the valve to close. Conversely, when water levels drop, the float descends, opening the valve to allow water to enter.

Types of Float Valves

Traditionally, float valves have been simple mechanical devices. However, modern advancements have introduced electronic and smart float valves that enhance precision and control. Understanding the differences between these types is essential for selecting the right valve for a specific application.

How Float Valves Function

The functionality of float valves can be broken down into a step-by-step process. When the water level is below the desired point, the float rests at a lower position, keeping the valve open. As water fills the reservoir, the float rises, eventually reaching a point where it triggers the valve to close, preventing further water entry.

Applications of Float Valves

Float valves find extensive use in various industries and settings. From maintaining water levels in household tanks to controlling the flow in large industrial processes, these valves are versatile and indispensable. Their reliability makes them a preferred choice in different applications.

Advantages of Float Valves

Efficient water management, cost-effectiveness, and reliability are among the key advantages of float valves. The ability to automatically control water levels without the need for constant monitoring makes them invaluable in scenarios where precise water management is essential.

Challenges and Solutions

Like any mechanical device, float valves face challenges, including wear and tear, sediment buildup, and potential malfunctions. Regular maintenance and addressing these issues promptly are crucial for ensuring the continued functionality of float valves.

Innovations in Float Valve Technology

The integration of smart technology and the Internet of Things (IoT) has led to innovations in float valve technology. Smart float valves can provide real-time data on water levels, allowing for remote monitoring and control. These advancements contribute to more efficient and sustainable water management.

Choosing the Right Float Valve

Selecting the right float valve involves considering factors such as the intended application, water pressure, and durability. A variety of brands and models cater to different needs, and thorough research is essential for making an informed decision.

Installation and Maintenance Tips

Proper installation and routine maintenance are crucial for ensuring the longevity and optimal performance of float valves. This includes checking for leaks, cleaning components, and lubricating moving parts. Following manufacturer guidelines is key to effective maintenance.

Float Valves in Agriculture

In the agricultural sector, float valves play a vital role in irrigation systems. Farmers benefit from the automatic regulation of water levels, ensuring crops receive the necessary irrigation without wastage.

Float Valves vs. Other Valve Types

Comparing float valves with pressure valves highlights the advantages of the former. While pressure valves rely on the force of the incoming water, float valves offer a more controlled and automated approach, making them suitable for a wide range of applications.

Environmental Impact of Float Valves

Float valves contribute to water conservation and sustainability. By efficiently managing water levels, these valves help reduce wastage, making them environmentally friendly choices in the face of increasing water scarcity.

Future Trends in Float Valve Technology

Looking ahead, the future of float valves involves continued innovation. Predictions include improved sensor technology, enhanced connectivity, and a focus on environmental sustainability. As technology evolves, float valves are likely to become even more integral to efficient water management.

Conclusion

In conclusion, float valves are indispensable components in fluid control systems, offering precision, reliability, and efficiency. From traditional mechanical valves to modern smart technologies, the evolution of float valves continues to contribute to various industries, ensuring optimal water management.

FAQs

- Are float valves suitable for all types of fluids?

- Float valves are primarily designed for water applications. While some may work with other fluids, it's essential to check the specifications and compatibility.

- Do float valves require frequent maintenance?

- Regular maintenance is recommended to ensure optimal performance. This includes checking for leaks, cleaning components, and addressing any issues promptly.

- Can float valves be used in gravity-fed systems?

- Yes, float valves can be adapted for use in gravity-fed systems, providing a controlled flow of water based on the water level.

- What is the lifespan of a typical float valve?

- The lifespan of a float valve depends on factors such as usage, water quality, and maintenance. With proper care, they can last for many years.

- Are smart float valves more complicated to install?

- Smart float valves may have additional installation requirements, but they often come with user-friendly guides. Following manufacturer instructions is crucial for a successful installation.

Comments

Post a Comment