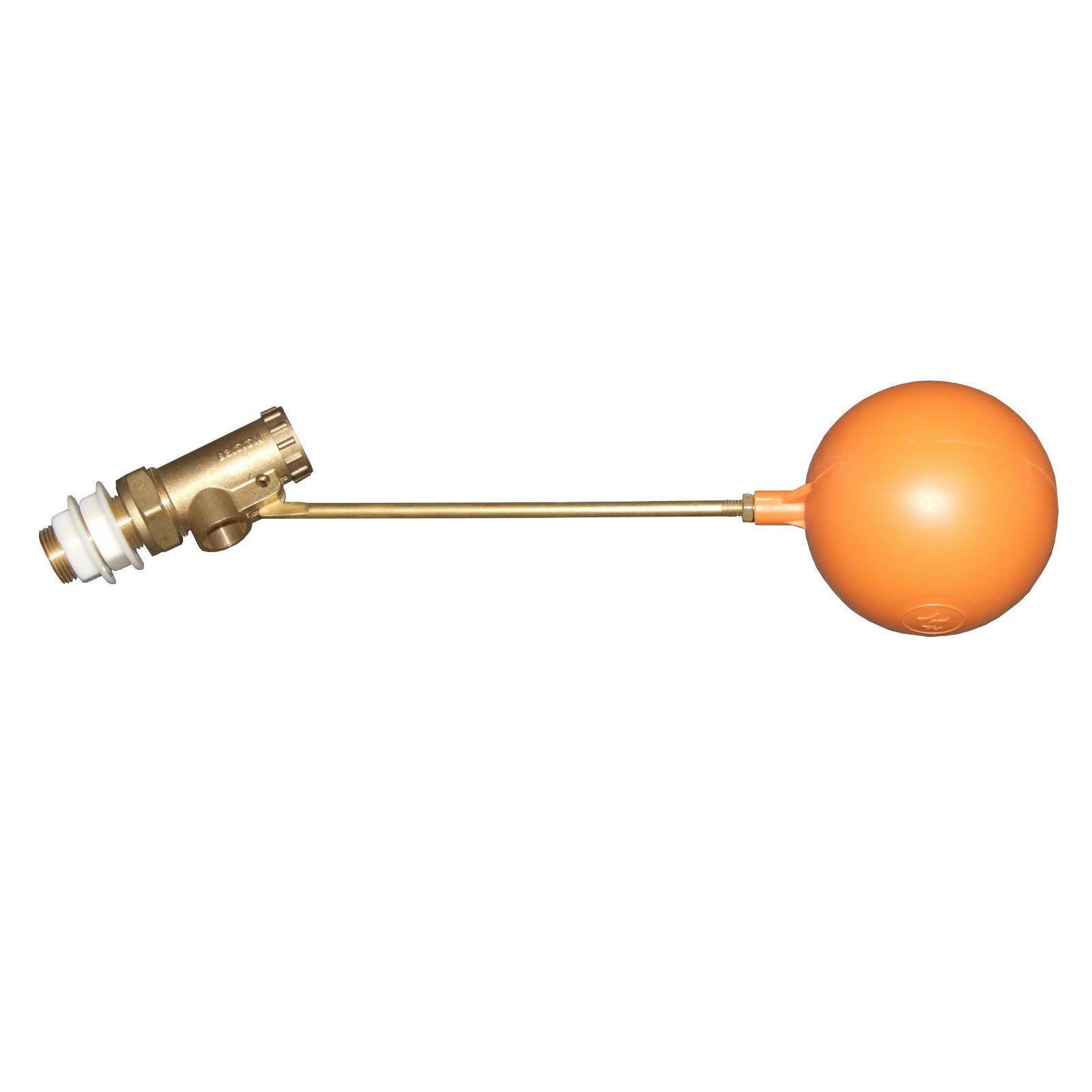

Brass Ball Float Valve

Brass Ball Float Valve: Enhancing Fluid Control Efficiency

Introduction

Brass ball float valves have become integral components in fluid control systems across various industries. This article explores the intricacies of these valves, from their basic components to practical applications and maintenance.

Components of Brass Ball Float Valve

Understanding the key components is crucial. The brass ball, valve body, float arm, and lever mechanism work in harmony to regulate fluid flow effectively.

How Brass Ball Float Valves Work

Explore the normal operating position, closing mechanism, and applications in fluid control, shedding light on the functionality that sets these valves apart.

Advantages of Using Brass Ball Float Valves

Discover the durability, corrosion resistance, and high-temperature resistance that make brass ball float valves a preferred choice in fluid control systems.

Common Applications

From water tanks to plumbing systems and industrial processes, delve into the versatile applications of brass ball float valves.

Brass Ball Float Valve Maintenance

Learn about regular inspection, cleaning procedures, and troubleshooting tips to ensure the longevity and optimal performance of these valves.

Choosing the Right Brass Ball Float Valve

Size considerations, material selection, and pressure ratings are pivotal factors when selecting the appropriate valve for a specific application.

Installation Guidelines

Get insights into proper positioning in water tanks, connection in plumbing systems, and installation tips for industrial settings.

Brass Ball Float Valve Variants

Explore miniature float valves, adjustable arm float valves, and high-pressure float valves, understanding their unique features.

Case Studies

Real-world examples showcase successful implementations and challenges overcome, providing practical insights.

Future Trends in Brass Ball Float Valve Technology

Look into the future of these valves, considering innovations in design, integration with smart systems, and environmental considerations.

User Testimonials

Read about positive experiences and real-world applications from users who have benefited from brass ball float valves.

Conclusion

Recap the benefits of brass ball float valves and explore their promising future prospects in fluid control systems.

FAQs

- How often should I inspect my Brass Ball Float Valve?Regular inspection is recommended at least once every six months to ensure optimal performance.

- Can Brass Ball Float Valves be used with corrosive fluids?Yes, brass ball float valves are resistant to corrosion, making them suitable for use with various fluids.

- Are there any safety precautions during installation?Always follow safety guidelines, ensuring proper valve sizing, and wear appropriate protective gear during installation.

- What is the typical lifespan of a Brass Ball Float Valve?With proper maintenance, brass ball float valves can have a lifespan of 5 to 10 years or more.

- Can I replace components of the valve if needed?Yes, most brass ball float valves allow for the replacement of individual components, extending their usability.

Comments

Post a Comment